Magnetic Devices

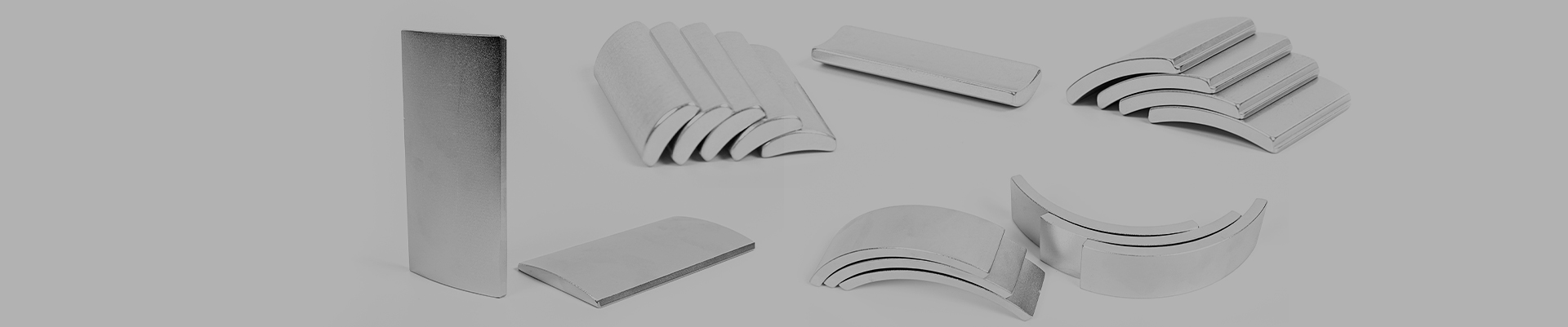

Operating Principle:

The operating principle of Magnetic Devices transfer torque from motor end to load end through the air gap. And there is no connection between the transmission side and load side of the equipment. A strong rare-earth magnetic field on one side of the transmission and an induced current from a conductor on the other side interact to create torque. By changing the air gap spacing, the torsion force can be precisely controlled and so that the speed can be controlled.

Products Advantages:

The permanent magnet drive replaces the connection between the motor and the load with an air gap. The air gap eliminates harmful vibration, minimizes wear, improves energy efficiency, extends motor life, and protects equipment from overload damage. The result:

Save energy

Enhanced reliability

Reduce the maintenance costs

Improved process control

No harmonic distortion or energy quality issues

Capable of operating in harsh environments

The Motor

Samarium cobalt alloy has been used for rare earth permanent magnet motors since 1980s. Product types include: Servo motor, drive motor, automobile starter, ground military motor, aviation motor and so on and a part of product is exported. The main characteristics of samarium cobalt permanent magnet alloy are:

(1). The demagnetization curve is basically a straight line, the slope is close to the inverse permeability. That is, the recovery line is approximately coincident with the demagnetization curve.

(2). It has great Hcj, it has the strong resistance to demagnetization.

(3). It has a high (BH)maximum magnetic energy product.

(4). The reversible temperature coefficient is very small and the magnetic temperature stability is good.

Because of the above characteristics, the rare earth samarium cobalt permanent magnet alloy is especially suitable for the application of the open circuit state, pressure situation, demagnetizing condition or dynamic condition, suitable for manufacturing small volume components.

Motor can be divided into DC motor and AC motor according to the type of power supply.

(1). According to the structure and working principle, DC motor can be divided into:

Brushless DC motor and brush DC motor.

Brush DC motor can be divided into: permanent magnet DC motor and electromagnetic DC motor.

Electromagnetic DC motor can be divided into: series DC motor, shunt DC motor, other DC motor and compound DC motor.

Permanent magnet DC motor can be divided into: rare earth permanent magnet DC motor, ferrite permanent magnet DC motor and Alnico permanent magnet DC motor.

(2). AC motor can also be divided into: single-phase motor and three-phase motor.

Electroacoustic

Operating Principle:

It is to make the current through the coil to produce a magnetic field, utilize the excitation out of the magnetic field and the original loudspeaker magnetic field action to produce vibration. It is the most commonly used loudspeaker.

It can be roughly divided into the following main parts:

Power system: including the voice coil (also the electric coil), the coil is usually fixed with the vibration system, through the diaphragm to convert the vibration of the coil into sound signals.

Vibration system: including sound film, that is, horn diaphragm, diaphragm. Diaphragm can be made of a variety of materials. It can be said that the sound quality of loudspeaker is largely determined by the materials and manufacturing process of diaphragm.

According to the different installation methods of its magnets, it can be divided into:

External magnet: wrap the magnet around the voice coil, so make the voice coil bigger than the magnet. The size of the outer voice coil is increased, so that make the diaphragm contact area larger, and the dynamic is better. The increased size voice coil is also with the higher heat dissipation efficiency.

Inner magnet: the voice coil is built inside the magnet, so the voice coil size is much smaller.

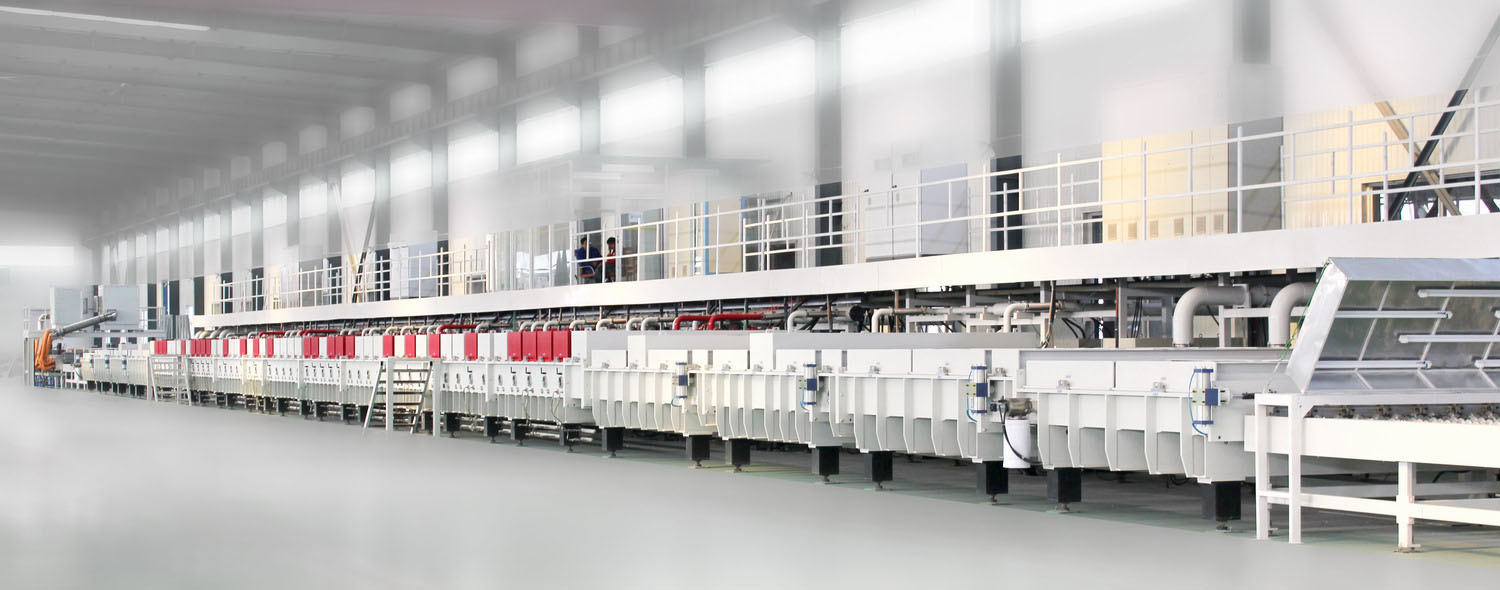

Coating Equipment

The basic principle of magnetron sputtering coating equipment is that electrons collide with argon atoms in the process of accelerating to the substrate under the action of electric field, then ionize a large number of argon ions and electrons, and the electrons fly to the substrate. Under the action of electric field, argon ion accelerates to bombard the target, sputtering a large number of target atoms, as neutral target atoms (or molecules) deposited on the substrate to form films. Secondary electron in the process of accelerating flying to the substrate affected by the Magnetic field lorenzo force, it is bounded within the plasma region close to the target, the plasma density in this area is very high, secondary electron under the action of magnetic field around the target surface as a circular motion, the electron motion path is very long, constantly argon atom collision ionization out large amounts of argon ion in the process of movement to bombardment of target. After a number of collisions, the energy of the electrons gradually decreases, and they get rid of the magnetic field lines, away from the target, and eventually deposit on the substrate.

Magnetron sputtering is to use magnetic field to bind and extend the motion path of electrons, change the motion direction of electrons, improve the ionization rate of working gas and effectively use the energy of electrons. The interaction between the magnetic field and the electric field (E X B drift) causes individual electron trajectory appear in a three-dimensional spiral rather than just circumferential motion at the target surface. As for the target surface circumferential sputtering profile, it is the magnetic field lines of target source magnetic field are circumferential shape. The distribution direction has great influence on film formation.

Magnetron sputtering is characterized by high film forming rate, low substrate temperature, good film adhesion, and large area coating. The technology can be divided into DC magnetron sputtering and RF magnetron sputtering.

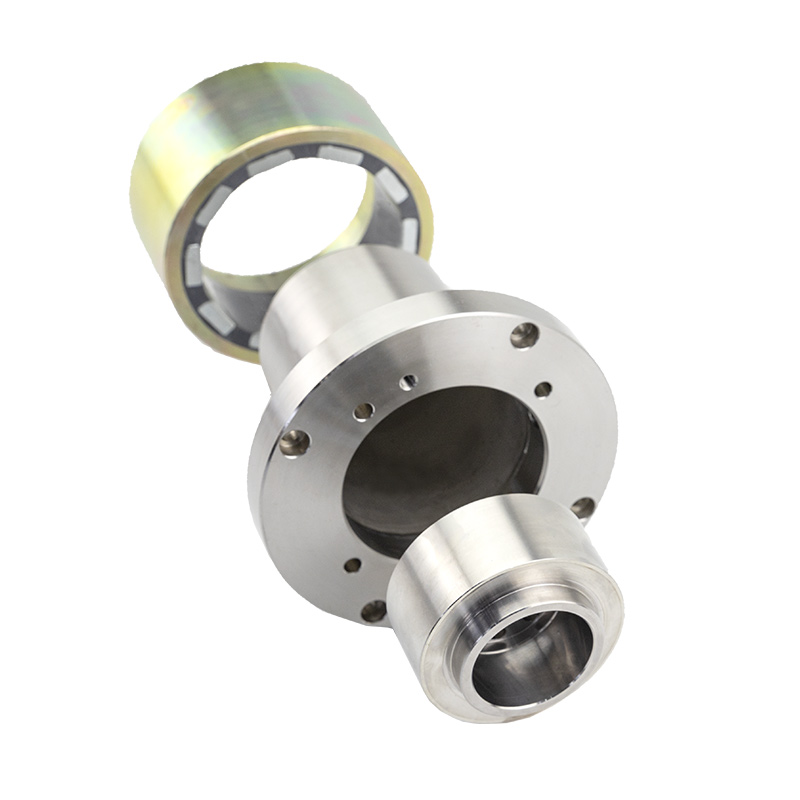

Wind Power Generation

Permanent magnet wind generator adopts high performance sintered NdFeb permanent magnets, high enough Hcj can avoid the magnet loses its magnetism at high temperature. The life of the magnet depends on the substrate material and surface anti-corrosion treatment. The anti-corrosion of NdFeb magnet should start from manufacturing.

A large permanent magnet wind generator usually uses thousands of NdFeb magnets, each pole of the rotor makes up many of magnets. The consistency of rotor magnetic pole requires the consistency of magnets, including the consistency of dimensional tolerance and magnetic properties. Uniformity of magnetic properties includes the magnetic variation between individuals is small and the magnetic properties of individual magnets should be uniform.

To detect the magnetic uniformity of a single magnet, it is necessary to cut the magnet into several small pieces and measure its demagnetization curve. Test whether the magnetic properties of a batch is consistent in the process of production. It is necessary to extract magnet from different parts in the sintering furnace as samples and measure the demagnetization curve of them. Because measuring equipment is very expensive, it is almost impossible to ensure the integrity of each magnet which is being measured. Therefore, it is impossible to do full product inspection. The consistency of NdFeb magnetic properties must be guaranteed by production equipment and process control.

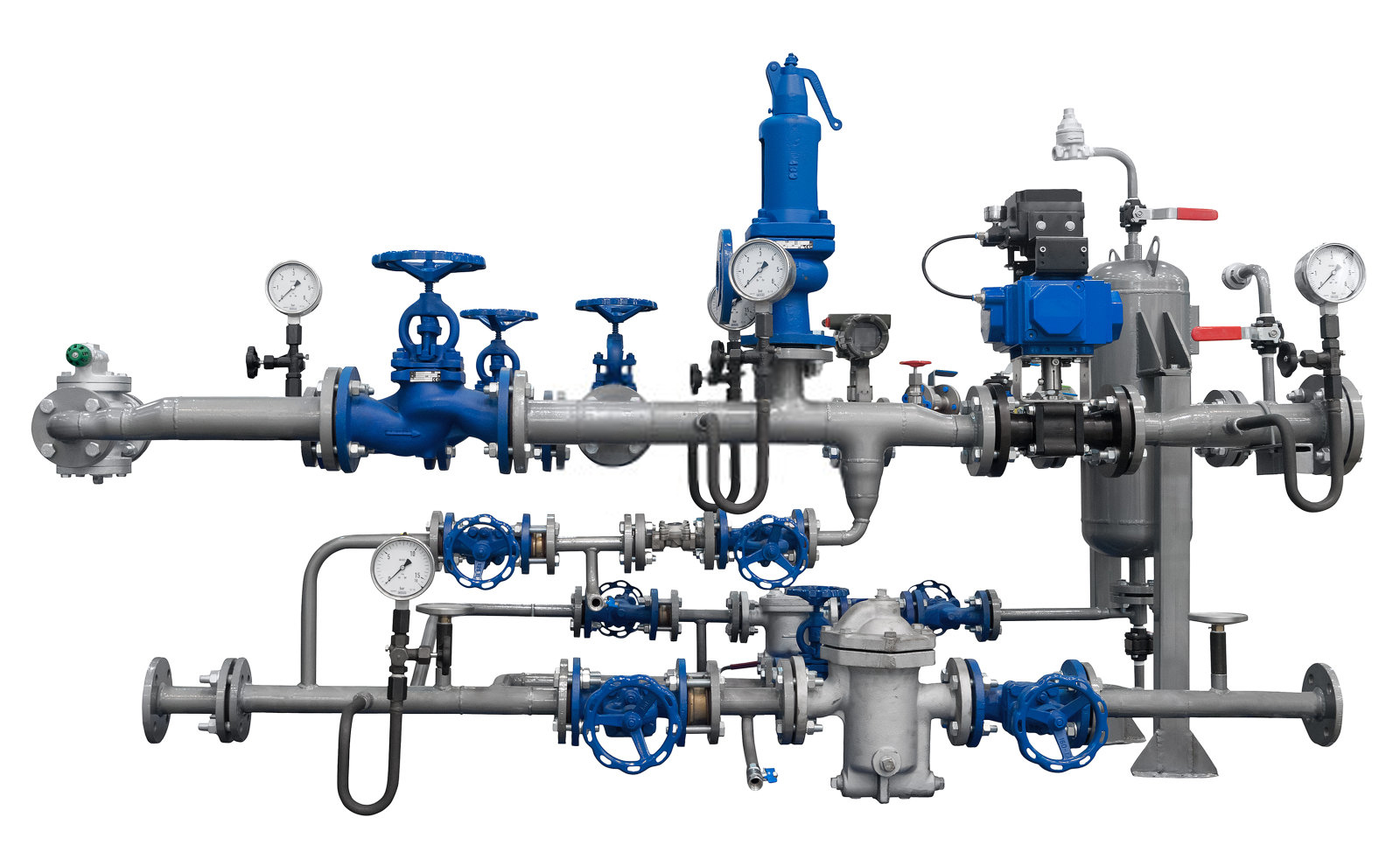

Industrial Automation

Automation refers to the process in which machine equipment, system or process achieves the expected goal through automatic detection, information processing, analysis, judgment and manipulation according to the requirements of people without the direct participation of people or less people. Automation technology is widely used in industry, agriculture, military, scientific research, transportation, business, medical, service and family. The use of automation technology can not only liberate people from heavy physical labor, part of mental labor and harsh, dangerous working environment, but also expand the function of human organs, greatly improve labor productivity, enhance the ability of human understanding and transformation of the world. Therefore, automation is an important condition and significant symbol of modernization of industry, agriculture, national defense and science and technology. As a part of the automated energy supply, magnet has very significant product characteristics:

1. No spark, especially suitable for explosive sites;

2. Good energy saving effect;

3. Soft start and soft stop, good braking performance

4. Small volume, large processing.

Aerospace Field

Rare earth cast magnesium alloy is mainly used for long-term 200 ~ 300℃, which has good high temperature strength and long-term creep resistance. The solubility of rare earth elements in magnesium is different, and the increasing order is lanthanum, mixed rare earth, cerium, praseodymium and neodymium. Its good influence also increases on mechanical properties at room temperature and high temperature. After heat treatment, ZM6 alloy with neodymium as the main additive element developed by AVIC not only has high mechanical properties at room temperature, but also has good transient mechanical properties and creep resistance at high temperature. It can be used at room temperature and can be used for a long time at 250℃. With the appearance of new cast magnesium alloy with yttrium corrosion resistance, the cast magnesium alloy is again popular in foreign aviation industry in recent years.

After adding an appropriate amount of rare earth metals to magnesium alloys. The addition of rare earth metal to magnesium alloy can increase the fluidity of the alloy, reduce the microporosity, improve the air tightness and remarkably improve the phenomenon of hot cracking and porosity, so that the alloy still has high strength and creep resistance at 200-300 ℃.

Rare earth elements play a significant role in improving the properties of superalloys. Superalloys are used in the hot end parts of aeroengines. However, the further improvement of aero-engine performance is limited due to the decrease of oxidation resistance, corrosion resistance and strength at high temperature.

Household Appliances

Domestic Appliance mainly refer to all kinds of electrical and electronic appliances used in homes and similar places. Also know as civil appliances, household appliances. Domestic Appliance liberate people from heavy, trivial and time-consuming housework, create a more comfortable and beautiful, more conducive to physical and mental health of the living and working environment for human beings, and provide rich and colorful entertainment conditions, it has become a necessity of modern family life.

Household appliances have nearly a century of history, the Unites States is considered to be the birthplace of household appliances. The scope of household appliances varies from country to country, and the world has not yet formed a unified classification of household appliances. In some countries, lighting appliances are listed as household appliances, and audio and video appliances are listed as cultural and entertainment appliances, which is also included electronic toys.

Daily common: The door on the front door sucks, the motor inside the electronic door lock, sensors, TV sets, magnetic strips on refrigerator doors, high-end variable frequency compressor motor, air conditioner compressor motor, fan motor, computer hard drives, speakers, the headset speaker, range hood motor, washing machine motor and so on will use magnet.

Automobile Industry

From the perspective of the industrial chain, 80% of rare earth minerals are made into permanent magnet materials through mining and smelting and reprocessing. Permanent magnet materials are mainly used in new energy industries such as motor of new energy vehicle and wind generator. Therefore, rare earth as an important new energy metal has attracted much attention.

It is reported that the general vehicle has more than 30 parts used rare earth permanent magnets, and the high-end car is more than 70 parts need to use rare earth permanent magnet material, to complete a variety of control actions.

"A luxury car needs about 0.5kg-3.5kg of rare earth permanent magnet material, and these amounts are even larger for new energy vehicles. Each hybrid consumes 5kg NdFeb more than a conventional car. Rare earth permanent magnet motor replaces the traditional motor to use more than 5-10kg NdFeb in the pure electric vehicles. “The industry participant pointed out.

In terms of the sales percentage in 2020, pure electric vehicles account for 81.57%, and the rest are mostly hybrid vehicles. According to this ratio, 10,000 new energy vehicles will need about 47 tons of rare earth materials, about 25 tons more than fuel cars.

New Energy Sector

We all have a basic understanding of new energy vehicles. Batteries, motors and electronic control are indispensable to a new energy vehicle. The motor plays the same role as the engine of traditional energy vehicles, which is equivalent to the heart of the car, while the power battery is equivalent to the fuel and the blood of the car, and the most indispensable part of the production of the motor is rare earth. The main raw materials for manufacturing modern super permanent magnet materials are Neodymium, Samarium, Praseodymium, Dysprosium and so on. NdFeb has 4-10 times higher magnetism than ordinary permanent magnet materials, and is known as the "king of permanent magnet".

Rare earths can also be found in components such as power batteries. The current common ternary lithium batteries, its full name is " Ternary Material Battery", generally refers to using nickel cobalt manganese acid lithium (Li (NiCoMn) O2, sliding) lithium nickel or cobalt aluminate (NCA) ternary positive electrode material of lithium battery. Make Nickel Salt, Cobalt Salt, Manganese Salt as three different proportions of ingredients for different adjustments, so they called “Ternary”.

As for the addition of different rare earth elements to the positive electrode of ternary lithium battery, the preliminary results show that, due to the large rare earth elements, some elements can make the battery charge and discharge faster, longer service life, more stable battery used, etc., it can be seen that rare earth lithium battery is expected to become the main force of the new generation of power battery. So rare earth is a magic weapon for key car parts.

Medical Apparatus and Instruments

In terms of medical instruments, laser knife made of laser material containing rare earth can be used for fine surgery, optical fiber made of lanthanum glass can be used as a light conduit, which can clearly observe the human stomach lesions. A rare earth ytterbium element can be used for brain scanning and chamber imaging. X-ray intensifying screen made a new type of rare earth fluorescent material, compared to the original use of calcium tungstate intensifying screen shooting 5 ~ 8 times higher efficiency, and can shorten the exposure time, reduce the human body by radiation dose, shooting has been greatly improved clarity, apply an appropriate amount of rare earth screens can put a lot of difficult original diagnosis of pathological changes more accurately diagnosed.

Use of rare earth permanent magnet materials made of magnetic resonance imaging (MRI) is a new technology applied in the 1980s medical equipment, which use a large stable uniform magnetic field to send a pulse wave to human body, make human body produce resonance hydrogen atom and absorb energy, then suddenly closed magnetic field. The release of the hydrogen atoms will absorb energy. As the hydrogen distribution in the human body each organization is different, release energy of different length of time, through the electronic computer to receive different information to analyze and process, just can be restored and separated out of the body's internal organs of the image, to distinguish normal or abnormal organs, identify the nature of the disease. Compared with X-ray tomography, MRI has the advantages of safety, no pain, no damage and high contrast. The emergence of MRI is regarded as a technological revolution in the history of diagnostic medicine.

The most widely used in medical treatment is magnetic hole therapy with rare earth permanent magnet material. Due to the high magnetic properties of rare earth permanent magnetic materials, and can be made into various shapes of magnetic therapy appliances, and not easy to demagnetization, it can be used on the body meridians acupoints or pathological areas, better than the traditional magnetic therapy effect. Rare earth permanent magnet materials are made of magnetic therapy products such as magnetic necklace, magnetic needle, magnetic health care earpiece, fitness magnetic bracelet, magnetic water cup, magnetic stick, magnetic comb, magnetic knee protector, magnetic shoulder protector, magnetic belt, magnetic massager, etc., which have the functions of sedation, pain relief, anti-inflammatory, depressurization, antidiarrhea and so on.

Instruments

Auto Instrument Motor Precision Magnets: It is generally used in SmCo Magnets and NdFeb Magnets. Diameter between 1.6-1.8, height between 0.6-1.0. Radial Magnetizing with Nickel plating.

Magnetic flip level meter according to the buoyancy principle and magnetic coupling principle of work. When the liquid level in the measured container rises and falls, the float in the leading tube of the magnetic flip plate level meter also rises and falls. The permanent magnet in the float is transferred to the field indicator through magnetic coupling, driving the red and white flip column to flip 180°. When the liquid level rises, the flip column turns from white to red, and when the liquid level drops, the flip column turns from red to white. The red and white boundary of the indicator is the actual height of the liquid level in the container, so as to indicate the liquid level.

Due to the magnetic coupling isolator closed structure. Especially suitable for flammable, explosive and corrosive toxic liquid level detection. So that the original complex environment liquid level detection means become simple, reliable and safe.