Magnet Linear Motor

PRODUCT INTRODUCTION

A linear motor is an electric motor that has had its stator and rotor "unrolled" so that instead of producing a torque(rotation) it produces a linear force along its length. However, linear motors are not necessarily straight. Characteristically, a linear motor's active section has ends, whereas more conventional motors are arranged as a continuous loop.

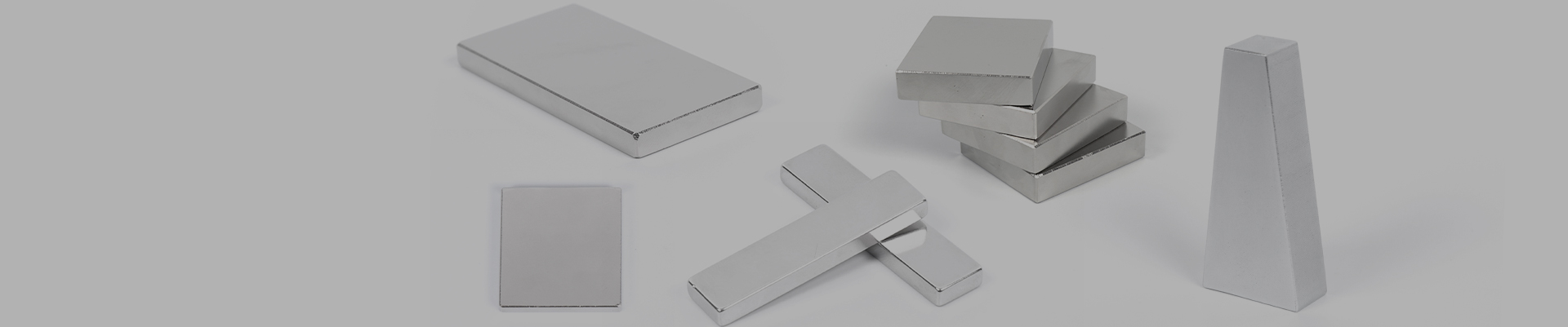

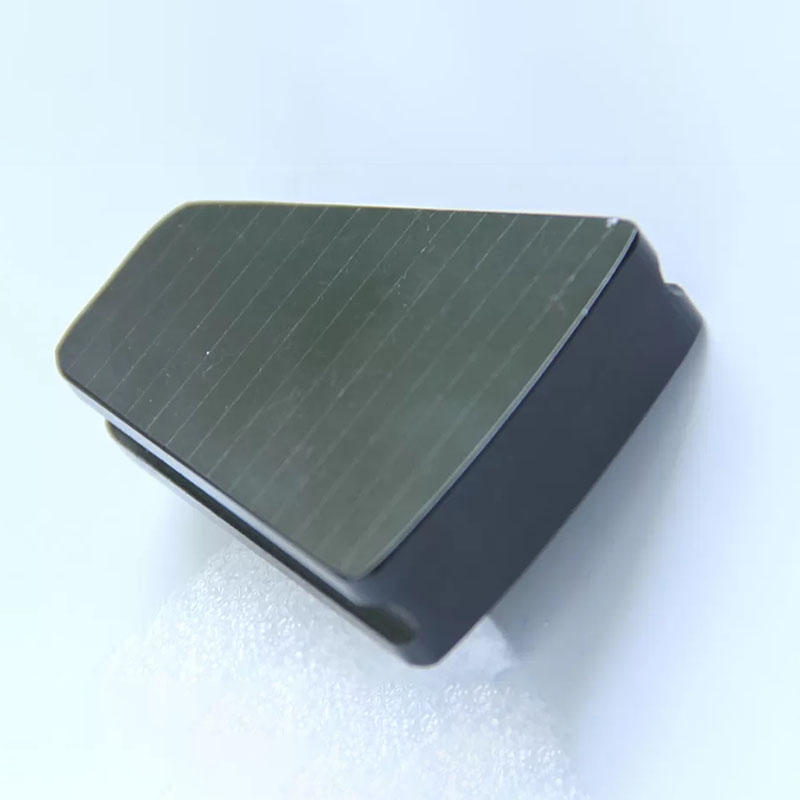

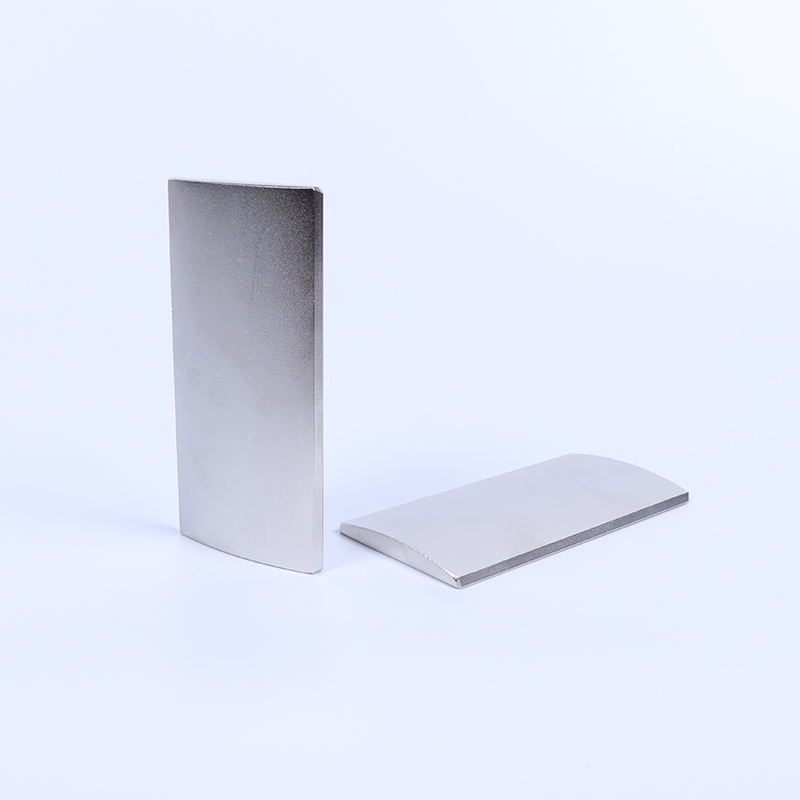

1.Materials

Magnet: Neodymium Magnet

Hardware part: 20# steel, martensitic stainless steel

2. Application

"U-channel" and "flat" brushless linear servo motors have proven ideal for robots, actuators, tables/stages, fiberoptics/photonics alignment and positioning, assembly, machine tools, semiconductor equipment, electronic manufacturing, vision systems, and in many other industrial automation applications.

WHY CHOOSE LINEAR MOTOR?

1. Dynamic performance

Linear motion applications have a wide range of dynamic performance requirements. Depending on the specifics of a system's duty cycle, the peak force and maximum speed will drive the selection of a motor:

An application with a light payload that requires very high speed and acceleration will typically utilize an ironless linear motor (that has a very light moving part containing no iron). As they have no attraction force, ironless motors are preferred with air bearings, when the speed stability has to be below 0.1%.

2. Wide force-speed range

Direct drive linear motion can provide high force over a wide range of speeds, from a stalled or low speed condition to high velocities. Linear motion can achieve very high velocities (up to 15 m/s) with a trade off in force for iron core motors, as technology becomes limited by eddy current losses. Linear motors achieve very smooth velocity regulation, with low ripple. The performance of a linear motor over its velocity range can be seen in the force-speed curve present in the corresponding data sheet.

3. Easy integration

Magnet linear motion are available in a wide range of sizes and can be easily adapted to most applications.

4. Reduced cost of ownership

Direct coupling of the payload to the motor's moving part eliminates the need for mechanical transmission elements such as leadscrews, timing belts, rack and pinion, and worm gear drives. Unlike brushed motors, there is no contact between the moving parts in a direct drive system. Therefore, there is no mechanical wear resulting in excellent reliability and long lifetime. Fewer mechanical parts minimize maintenance and reduce the system cost.