Discount wholesale Permanent Magnet Bar - Lamination Neodymium magnet can reduce the eddy current loss – Xinfeng Detail:

PRODUCT INTRODUCTION

Laminated rare earth magnets can reduce eddy current losses in high-efficiency motors. Smaller eddy current losses mean lower heat and higher efficiency.

In permanent magnet synchronous motors, the eddy current losses in the rotor are ignored because the rotor and stator are rotating synchronously. In fact, stator slot effects, non-sinusoidal distribution of winding magnetic forces and harmonic magnetic potentials generated by harmonic currents in the coil winding also cause eddy current losses in the rotor, rotor yoke and metal permanent magnets binding the permanent magnet sheath

Since the maximum operating temperature of sintered NdFeB magnets is 220 ° C (N35AH), the higher the operating temperature, the lower the magnetism of the NdFeB magnets, the lower the conversion and power of the motor. This is called heat loss! These eddy current losses can lead to elevated temperatures, leading to local demagnetization of permanent magnets, which is particularly severe in some high speed or high frequency permanent magnet synchronous motor.

Heat loss is mainly caused by electromagnetic eddy current during motor operation. Therefore, multiple stacking methods (which require insulation between each magnet) to reduce this heat loss.

TECHNICAL REQUIREMENTS

1.The thinnest insulation, < 20 microns;

2.Performance at temperatures up to 220˚C;

3.Magnet layers from 0.5 mm and above are custom shaped and sized neodymium magnets.

SCOPE OF APPLICATION

High-speed permanent magnet motors, aerospace, automotive, motorsport and industrial markets are turning to laminated rare earth magnets and are working to balance the tradeoff between power and heat.

Advantages: it can reduce the energy loss caused by electromagnetic eddy current.

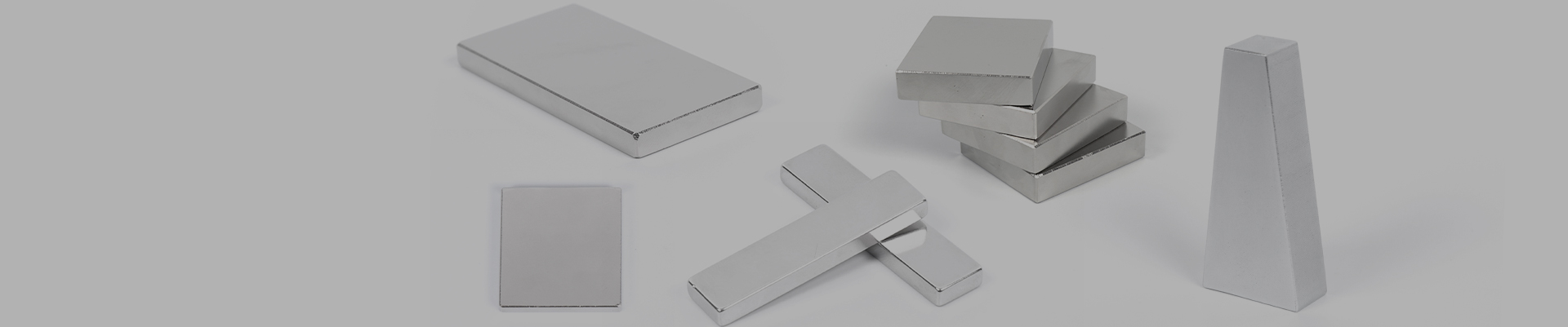

PRODUCT DISPLAY

15 section magnet with spray epoxy coating

Block laminated magnet

Laminate magnet fanshaped

Laminated magnet – arc

Laminated magnet – large arc

Laminated magnet block shape

Multiple bonded magnetic assemblies with grooves

Segmental laminated neodymium magnet

Smallest arc magnet

Product detail pictures:

Related Product Guide:

We know that we only thrive if we could guarantee our combined price tag competiveness and quality advantageous at the same time for Discount wholesale Permanent Magnet Bar - Lamination Neodymium magnet can reduce the eddy current loss – Xinfeng , The product will supply to all over the world, such as: Sao Paulo, Portugal, Angola, Really should any of these items be of interest to you, please let us know. We will be pleased to give you a quotation upon receipt of one's detailed specifications. We've our personal specialist R&D enginners to meet any of the requriements, We look forward to receiving your enquires soon and hope to have the chance to work together with you inside the future. Welcome to take a look at our organization.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.