High Quality Ndfeb Magnet - Application of magnet in permanent magnet coupling – Xinfeng Detail:

PRODUCT INTRODUCTION

Magnetic coupling is a coupling that transmits torque from one shaft, but it uses a magnetic field rather than a physical mechanical connection.

Magnetic couplings are often used in hydraulic pump and propeller systems because a static physical barrier can be placed between the two shafts to separate the fluid from the air operated by the motor. Magnetic couplings do not allow the use of shaft seals, which will eventually wear out and align with system maintenance, because they allow greater off-shaft error between the motor and the driven shaft

1.The Material

Magnet: neodymium magnet

Isolation sleeve: austenitic stainless steel, such as SS304, SS316. There are also industrial plastics, titanium alloys, copper sleeves or ceramics, etc.

Main parts: 20 # steel, martensitic stainless steel

2.The advantages

Magnetic couplings are used for standard applications.

Good sealing.

There is no contact with the torque transfer element.

No maintenance.

High efficiency optional.

3. Recommended application industry

- Chemical industry

- The oil and gas industry

- Refining

- Pharmaceutical industry

- A centrifugal pump

- Drive the mixer / agitator

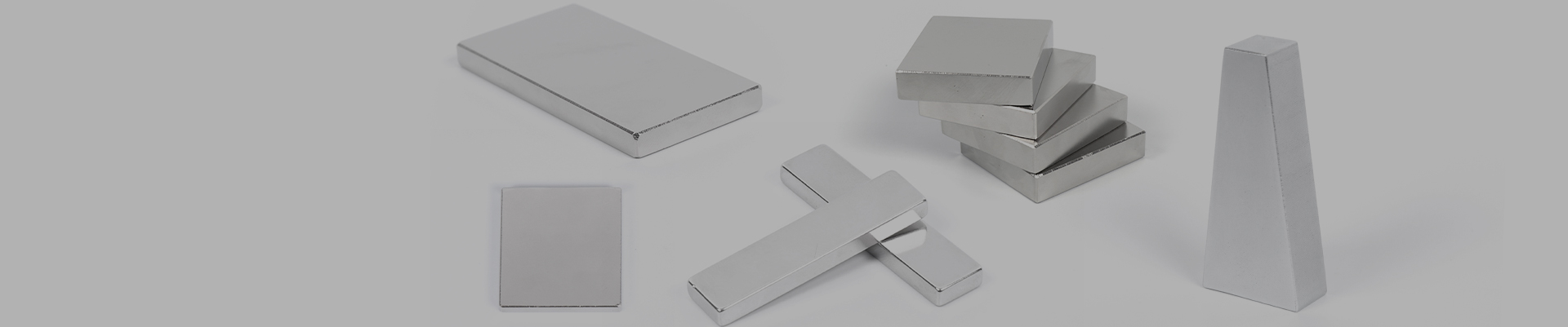

PRODUCT DISPLAY

Magnetic coupling – Inner and outer magnet assembly

Neodymium magnetic drive coupling

Permanent magnet coupling – internal magnet & isolated copper bushing

Product detail pictures:

Related Product Guide:

We emphasize advancement and introduce new products into the market each year for High Quality Ndfeb Magnet - Application of magnet in permanent magnet coupling – Xinfeng , The product will supply to all over the world, such as: Mecca, Benin, Dominica, With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!