High Quality Rubber Magnets - Rubber Magnet Strong Permanent Magnet – Xinfeng Detail:

PRODUCT INTRODUCTION

As a composite material, Rubber Magnet is made by mixing ferrite powder with rubber and finished through extrusion or rolling.

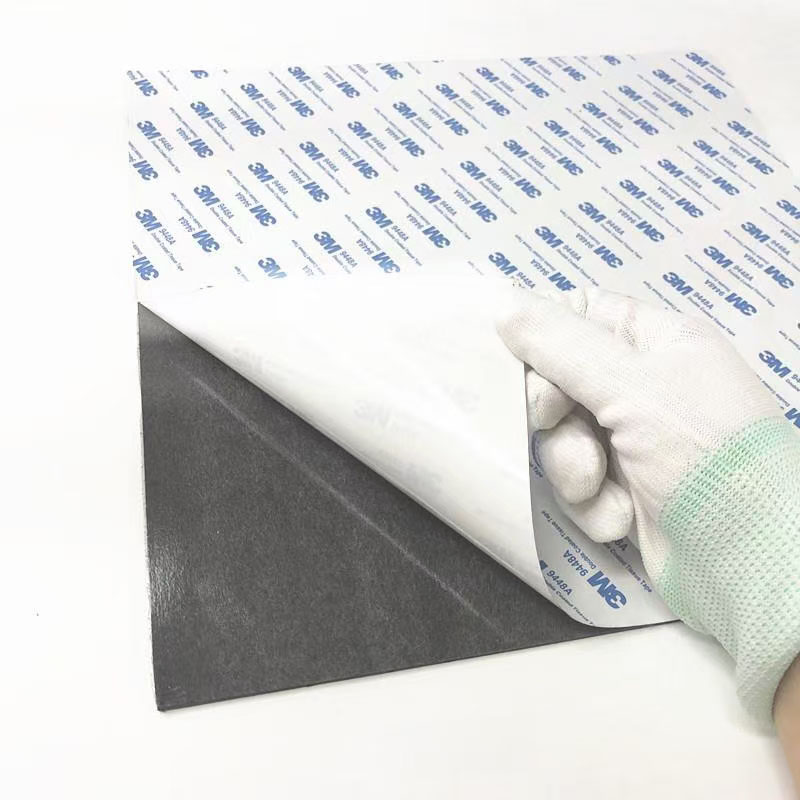

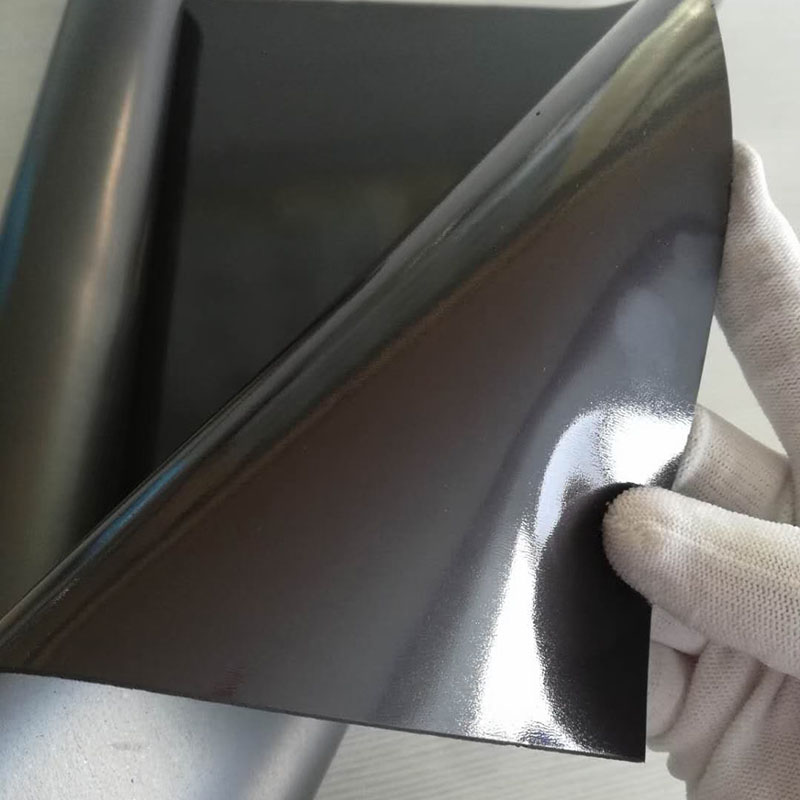

Rubber Magnet is highly flexible in itself, which can be used to produce special-shaped and thin-walled products. The finished or semi-finished product can be cut, punched, slitted or laminated tailed to specific need. It is high in consistency and precision. Good performance in impact resistance makes it non-breakable. And it has good resistance to demagnetization and corrosion.

Considering its low density, it is helpful in reducing the weight of device or machine. It can be used to produce full radial oriented magnets; laminated with PVC, PP synthetic paper, and double-sided tape, etc.; and make a variety of products. Abundant source makes it cheap in price.

There are two major types of Rubber Magnets, Isotropic and Anisotropic. Isotropic Rubber Magnet is weak in magnetic property. However, the Anisotropic Rubber Magnet is strong in magnetic property.

It is widely used in small precise motors, fridge door seal, magnetic teaching, continuous electricity switch, advertisement decoration, sensors, instruments & meters, toys, wireless communications, health care and various electronic appliances, etc.

PRODUCT DISPLAY

Product detail pictures:

Related Product Guide:

We not only will try our greatest to offer superb companies to just about every buyer, but also are ready to receive any suggestion offered by our shoppers for High Quality Rubber Magnets - Rubber Magnet Strong Permanent Magnet – Xinfeng , The product will supply to all over the world, such as: Pakistan, belarus, Berlin, As an experienced group we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of our company is to build up a satisfactory memory to all customers, and establish a long term win-win business relationship. Choose us, we always wait for your appearance!

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.