Quality Inspection for Ceramic Disk Magnets - Different types of neodymiun magnet with thread – Xinfeng Detail:

PRODUCT INTRODUCTION

Magnetic assembly include magnetic alloys and non-magnetic materials. Magnet alloys are so stiffness that even simple features are difficult to incorporate into the alloys. Installation and application specific features are easily incorporated into non-magnetic materials that normally form shell or magnetic circuit elements. The non-magnetic element will also buffer the mechanical stress of the brittle magnetic material and increase the overall magnetic strength of the magnet alloy.

Magnetic assembly usually have a higher magnetic force than general magnets because the flux conducting element (steel) of the component is usually an integral part of the magnetic circuit. By using magnetic induction, these elements will enhance the magnetic field of the component and focus it to the area of interest. This technique works best when magnetic components are used in direct contact with the workpiece. Even a small gap can greatly affect the magnetic force. These gaps can be actual air gaps or any coating or debris that separates the component from the workpiece.

Product Name: Neodymium magnet assembly with thread

Material: NdFeb magnet, 20 # steel

Coating: passivation and phosphating, Ni, Ni-Cu-Ni, Zn, CR3 + Zn, Tin, gold, silver, epoxy resin, teflon, etc.

Magnetization direction: radial magnetization, axial magnetization, etc.

Grade: N35-N52 (M.H.S.H.U.H.E.H.A)

Size: Customized

Purpose: Industrial applications

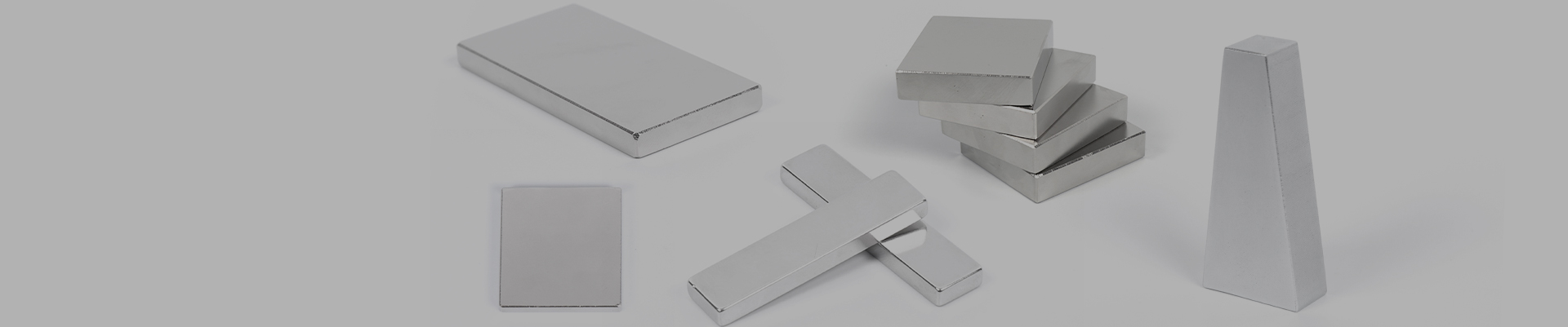

PRODUCT DISPLAY

Brass composite neodymium magnet cylinder assembly

Large ring magnetic assembly

Magnetic drive wheel for wall-climbing robot

Magnetic wrench parts

Neodymium magnet assembly with external thread

Neodymium magnet assembly with internal thread

Product detail pictures:

Related Product Guide:

We've our have sales staff, style and design staff, technical crew, QC team and package workforce. We've strict excellent control procedures for each system. Also, all of our workers are experienced in printing field for Quality Inspection for Ceramic Disk Magnets - Different types of neodymiun magnet with thread – Xinfeng , The product will supply to all over the world, such as: Jersey, Seychelles, Niger, We only supply quality items and we believe this is the only way to keep business continue. We can supply custom service too such as Logo, custom size, or custom merchandise etc that can according to customer's requirement.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!